3-Pole Intelligent Universal Circuit Breaker: 7 Powerful Advantages for Motor Protection with Electronic Trip Unit

Outline for 3-Pole Intelligent Universal Circuit Breaker with Electronic Trip Unit for Motor Protection

| Section | Details and LSI Keywords Covered |

|---|---|

| Introduction to 3-Pole Intelligent Universal Circuit Breaker | motor protection |

| Understanding Intelligent Universal Circuit Breakers | smart circuit breaker |

| Importance of Motor Protection in Power Systems | motor safety |

| Evolution from Thermal to Electronic Trip Units | electronic protection |

| Construction of 3-Pole Universal Circuit Breaker | breaker design |

| Role of Electronic Trip Unit in Motor Protection | digital trip unit |

| Protection Functions for Motors | overload, short circuit |

| Selectivity and Coordination with Motor Starters | coordination |

| Adjustable Protection Settings for Motors | current settings |

| Short-Circuit Withstand and Breaking Capacity | fault interruption |

| Thermal Memory and Motor Heating Considerations | thermal modeling |

| Intelligent Monitoring and Diagnostics | condition monitoring |

| Integration with PLC and SCADA Systems | automation |

| Installation in Motor Control Centers | MCC panels |

| Wiring Considerations for 3-Pole Motor Circuits | three-phase wiring |

| Safety Interlocks and Operational Reliability | operator safety |

| Energy Efficiency and Reduced Downtime | system efficiency |

| Applications in Industrial Motor Protection | industrial motors |

| Applications in Pumps, Compressors, and Fans | rotating equipment |

| Performance in Frequent Start-Stop Operations | duty cycles |

| Compliance with IEC and UL Motor Protection Standards | standards |

| Maintenance and Testing of Electronic Trip Units | testing |

| Common Motor Faults and Breaker Response | fault analysis |

| Comparison with Traditional Motor Protection Devices | comparison |

| Selecting the Right 3-Pole Intelligent Circuit Breaker | selection guide |

| Cost Efficiency and Lifecycle Benefits | ROI |

| Future Trends in Intelligent Motor Protection | smart protection |

| FAQs about 3-Pole Intelligent Universal Circuit Breaker | common questions |

| Conclusion on Intelligent Universal Circuit Breaker for Motors | summary |

Introduction

A 3-pole intelligent universal circuit breaker with electronic trip unit for motor protection is a critical component in modern industrial power systems. Motors are the backbone of industrial operations, driving pumps, compressors, conveyors, and production machinery. However, motors are also vulnerable to electrical faults that can cause costly damage and downtime.

To protect these valuable assets, intelligent circuit breakers equipped with electronic trip units provide precise, reliable, and adaptable protection. By combining high-performance switching with digital intelligence, these breakers ensure motors operate safely under a wide range of conditions.

Understanding Intelligent Universal Circuit Breakers

An intelligent universal circuit breaker is designed to provide advanced protection and control beyond traditional thermal or magnetic devices. The term “intelligent” refers to its ability to measure, analyze, and respond to electrical parameters in real time.

In a 3-pole configuration, the breaker protects three-phase motor circuits. This makes it ideal for industrial motors that require balanced phase protection and fast fault interruption.

Importance of Motor Protection in Power Systems

Electric motors represent a significant investment. Without adequate protection, faults such as overload, phase loss, or short circuits can quickly lead to overheating and failure.

Effective motor protection minimizes downtime, reduces maintenance costs, and enhances safety. A 3-pole intelligent universal circuit breaker ensures that motors are protected throughout their operating lifecycle.

Evolution from Thermal to Electronic Trip Units

Traditional motor protection relied on thermal overload relays. While effective, these devices had limited accuracy and flexibility.

Electronic trip units represent a major advancement. They provide precise sensing, programmable settings, and consistent performance regardless of ambient conditions. This evolution has transformed motor protection strategies.

Construction of 3-Pole Universal Circuit Breaker

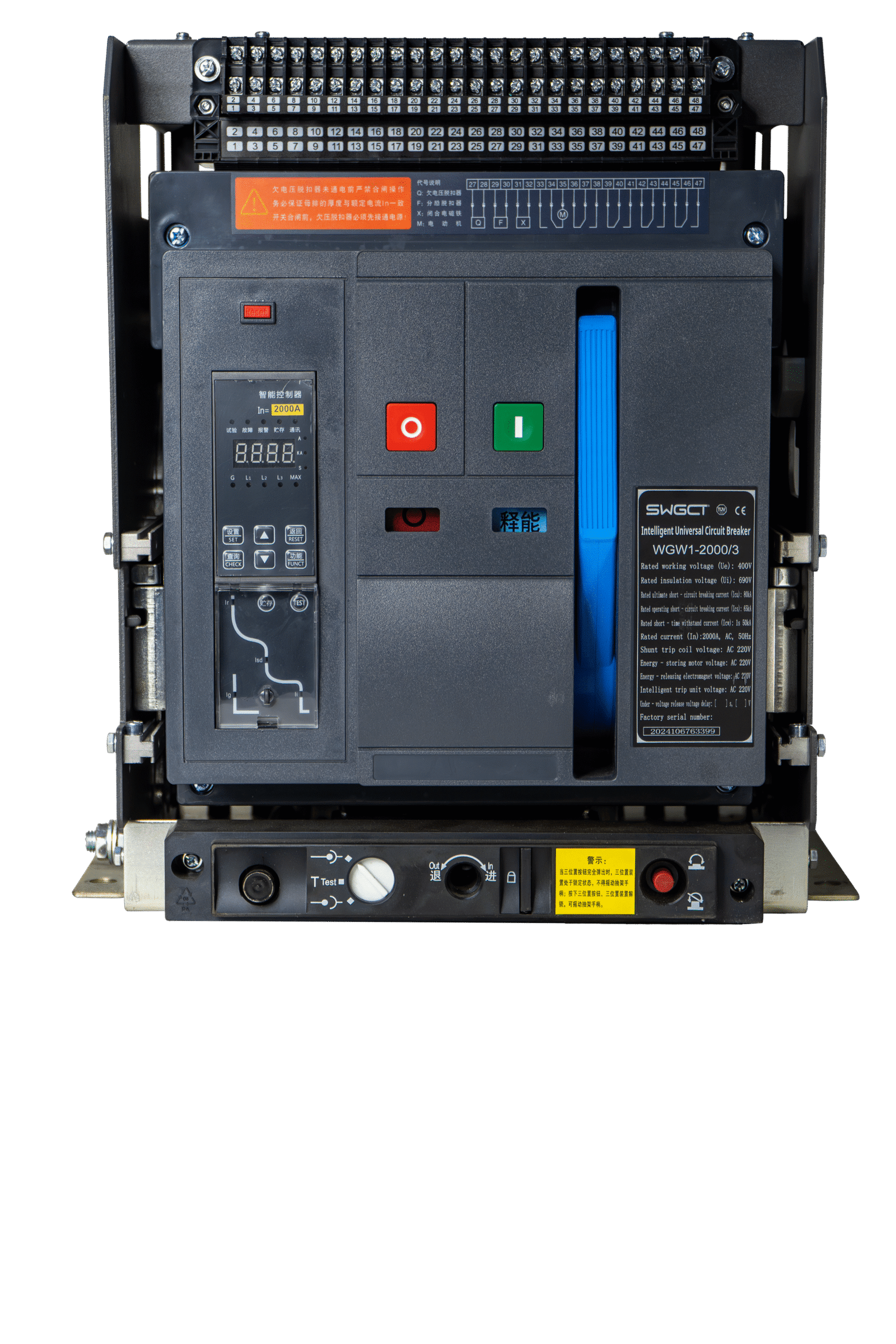

The breaker consists of three main current-carrying poles, a mechanical operating mechanism, arc extinguishing chambers, and an electronic trip unit.

Each pole interrupts one phase of the motor supply. The robust construction ensures reliable operation under high mechanical and electrical stress.

Role of Electronic Trip Unit in Motor Protection

The electronic trip unit continuously monitors current and voltage parameters. It compares these values against preset thresholds.

When abnormal conditions are detected, the trip unit sends a signal to open the breaker. This fast and accurate response prevents motor damage.

Protection Functions for Motors

A 3-pole intelligent universal circuit breaker provides multiple protection functions. These typically include overload protection, short-circuit protection, and phase imbalance detection.

Some models also include earth fault and under-voltage protection. Together, these functions offer comprehensive motor safety.

Selectivity and Coordination with Motor Starters

Proper coordination ensures that only the faulty motor circuit is disconnected. The breaker’s adjustable settings allow coordination with contactors and motor starters.

This selectivity minimizes disruption to other equipment. It also simplifies fault isolation and recovery.

Adjustable Protection Settings for Motors

Electronic trip units allow precise adjustment of current thresholds and time delays. These settings can be tailored to specific motor characteristics.

Customizable protection improves performance and reduces nuisance tripping. It ensures optimal protection for different motor types.

Short-Circuit Withstand and Breaking Capacity

Motors can draw very high currents during faults. The breaker must interrupt these currents safely.

A high breaking capacity ensures the breaker can handle severe short circuits. This capability is essential in industrial environments.

Thermal Memory and Motor Heating Considerations

Motors retain heat after operation. Electronic trip units incorporate thermal memory functions.

This feature accounts for residual heat and prevents premature restarting. It protects motors from cumulative thermal stress.

Intelligent Monitoring and Diagnostics

Advanced breakers provide diagnostic information such as fault history and load profiles.

This data supports predictive maintenance. It helps operators identify issues before they escalate into failures.

Integration with PLC and SCADA Systems

Many intelligent circuit breakers support communication interfaces. These interfaces enable integration with automation systems.

Remote monitoring and control improve operational efficiency. They also enhance visibility into motor performance.

Installation in Motor Control Centers

Motor control centers often house multiple breakers and starters. Compact design and modular construction simplify installation.

Proper spacing and wiring ensure reliable operation. Professional installation is essential for safety and compliance.

Wiring Considerations for 3-Pole Motor Circuits

Correct phase sequencing and secure connections are critical. Loose connections can cause overheating and imbalance.

Following wiring standards ensures reliable motor operation. Attention to detail reduces long-term issues.

Safety Interlocks and Operational Reliability

Safety features such as mechanical interlocks and clear status indicators protect operators.

Reliable operation under frequent switching enhances system dependability. Safety remains a top priority in motor protection.

Energy Efficiency and Reduced Downtime

Accurate protection reduces unnecessary trips. Motors operate within optimal parameters.

Reduced downtime improves productivity. Energy efficiency improves through stable motor operation.

Applications in Industrial Motor Protection

These breakers are widely used in manufacturing plants. They protect motors driving conveyors, mixers, and processing equipment.

Industrial environments demand robust and intelligent protection solutions.

Applications in Pumps, Compressors, and Fans

Pumps and compressors often operate continuously. Reliable protection prevents costly failures.

Fans and HVAC motors also benefit from precise electronic protection.

Performance in Frequent Start-Stop Operations

Some motors experience frequent starting. Electronic trip units accommodate these duty cycles.

This capability ensures reliable operation without nuisance tripping.

Compliance with IEC and UL Motor Protection Standards

Quality intelligent circuit breakers comply with international standards. Compliance ensures safety and performance.

Certified devices simplify regulatory approval and inspections.

Maintenance and Testing of Electronic Trip Units

Maintenance involves functional testing and visual inspection. Electronic trip units require minimal upkeep.

Periodic testing ensures readiness. Proper maintenance extends service life.

Common Motor Faults and Breaker Response

Common faults include overload, phase loss, and short circuits. The breaker responds quickly to isolate the fault.

Fast response minimizes damage. It also enhances safety.

Comparison with Traditional Motor Protection Devices

Traditional devices lack flexibility and diagnostics. Intelligent breakers offer superior accuracy and control.

This comparison highlights the advantages of modern protection solutions.

Selecting the Right 3-Pole Intelligent Circuit Breaker

Selection depends on motor rating, protection requirements, and system architecture.

Expert guidance ensures optimal selection. The right breaker maximizes protection and efficiency.

Cost Efficiency and Lifecycle Benefits

Although initial cost may be higher, lifecycle benefits are substantial.

Reduced downtime and maintenance deliver long-term savings.

Future Trends in Intelligent Motor Protection

Future systems will emphasize connectivity and analytics.

Smart breakers will play a key role in digitalized industrial environments.

FAQs

What is a 3-pole intelligent universal circuit breaker?

It is a breaker designed for three-phase circuits with advanced electronic protection.

Why use an electronic trip unit for motors?

It provides accurate, adjustable, and reliable protection.

Can it integrate with automation systems?

Yes, many models support PLC and SCADA integration.

Is it suitable for frequent motor starting?

Yes, electronic trip units handle varying duty cycles well.

Does it replace traditional overload relays?

In many cases, yes.

Is maintenance required?

Minimal periodic testing is recommended.

Conclusion

The 3-pole intelligent universal circuit breaker with electronic trip unit for motor protection represents a modern approach to safeguarding industrial motors. By combining precise electronic sensing with robust switching capability, it delivers superior protection, reliability, and operational insight.

As industries move toward smarter and more efficient systems, intelligent motor protection solutions will become increasingly essential. Investing in a high-quality intelligent circuit breaker ensures long-term performance, safety, and productivity.