Outline for Heavy-Duty 4-Pole Motorized Load Isolation Switch for Industrial Power Distribution

Heavy-Duty 4-Pole Motorized Load Isolation Switch: 11 Powerful Advantages for Industrial Power Distribution Safety

| Section | Details and LSI Keywords Covered |

|---|---|

| Introduction to Heavy-Duty 4-Pole Motorized Load Isolation Switch | industrial isolation, power safety |

| Understanding a Heavy-Duty 4-Pole Motorized Load Isolation Switch | load disconnect switch |

| Importance of 4-Pole Isolation in Industrial Power Distribution | neutral isolation, safety |

| Evolution of Motorized Load Isolation Switches | automation history |

| Core Components of Heavy-Duty Motorized Isolation Switch | motor drive, contacts |

| What Makes a Switch “Heavy-Duty” | current rating, durability |

| How a 4-Pole Motorized Load Isolation Switch Works | remote operation |

| Role of the Neutral Pole in 4-Pole Switches | fault prevention |

| Manual vs Motorized Load Isolation Switch | operational comparison |

| Integration with Industrial Power Distribution Systems | switchgear panels |

| Applications in Manufacturing Plants | machinery isolation |

| Applications in Utilities and Infrastructure | substations |

| Role in Data Centers and Critical Facilities | uptime protection |

| Safety Interlocking and Protection Features | mechanical interlocks |

| Remote Control and Automation Capabilities | SCADA, BMS |

| Installation Best Practices in Industrial Environments | wiring, mounting |

| Compliance with Industrial Electrical Standards | IEC, UL |

| Maintenance of Heavy-Duty Motorized Isolation Switch | lifecycle care |

| Common Faults and Troubleshooting | diagnostics |

| Energy Efficiency and Operational Reliability | low losses |

| Environmental and Mechanical Durability | harsh conditions |

| Selecting the Right Heavy-Duty 4-Pole Isolation Switch | rating guide |

| Cost and Lifecycle Value Analysis | long-term ROI |

| Future Trends in Motorized Isolation Switches | smart grids |

| FAQs about Heavy-Duty 4-Pole Motorized Load Isolation Switch | common questions |

| Conclusion on Heavy-Duty 4-Pole Motorized Load Isolation Switch | summary |

Introduction

A Heavy-duty 4-pole motorized load isolation switch for industrial power distribution is a critical safety and control device used in demanding electrical environments. Its primary role is to safely disconnect electrical loads from power sources while ensuring full isolation of all conductors, including the neutral. In industries where safety, reliability, and remote control are essential, this switch has become indispensable.

Unlike conventional disconnectors, a motorized isolation switch allows both local and remote operation. This capability supports modern industrial automation and enhances operator safety. As industrial power systems grow in scale and complexity, the importance of robust isolation solutions continues to increase.

Understanding a Heavy-Duty 4-Pole Motorized Load Isolation Switch

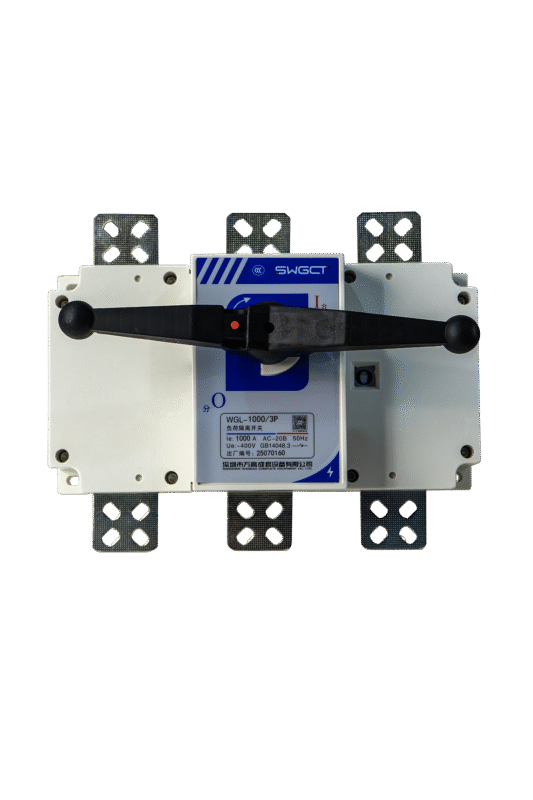

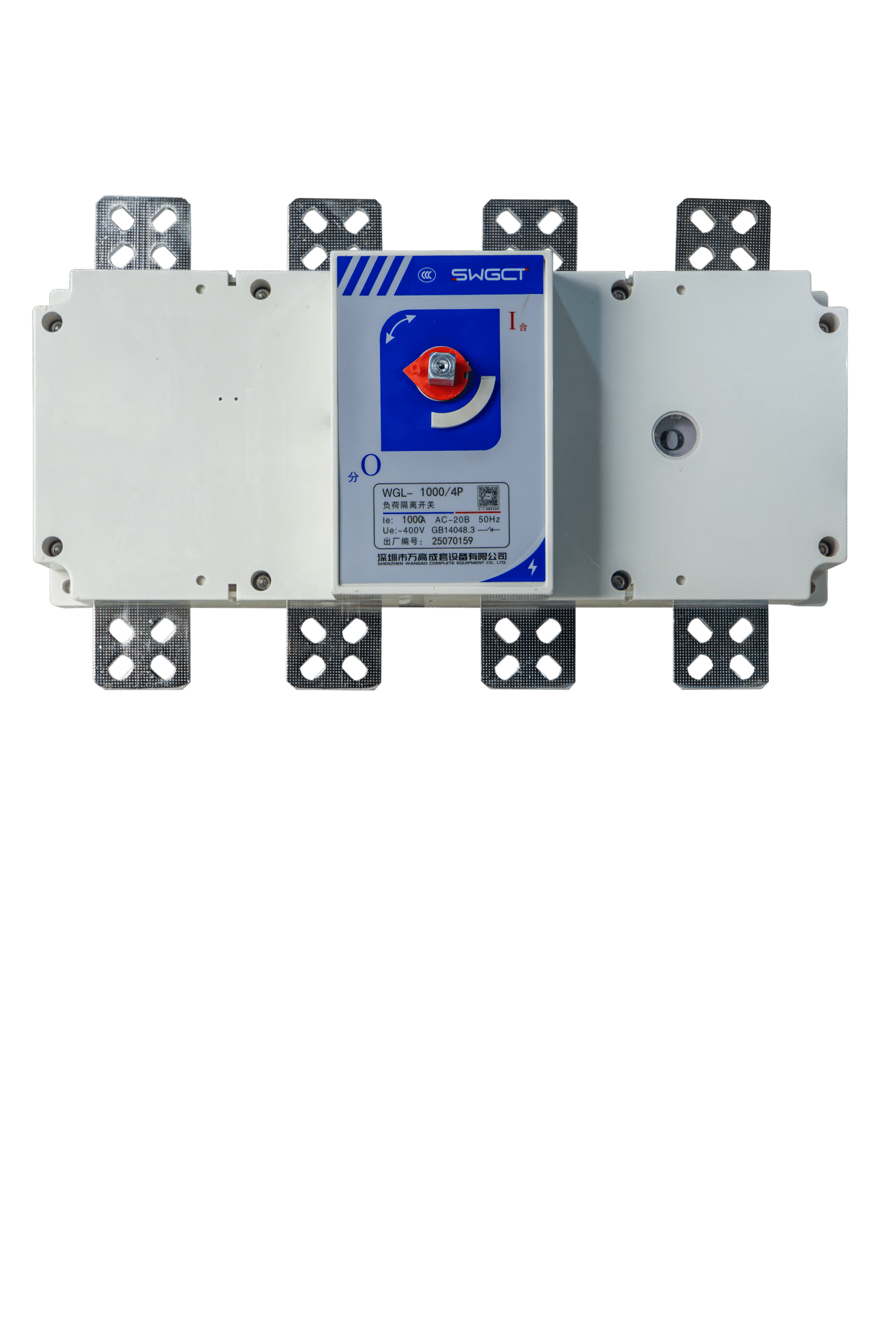

A heavy-duty 4-pole motorized load isolation switch is designed to disconnect three phase conductors and the neutral conductor simultaneously. The “motorized” aspect refers to an integrated electric motor that operates the switching mechanism automatically.

This design ensures consistent and reliable operation under load conditions. The switch is typically installed upstream of distribution panels, machinery, or critical loads, providing a clear and safe isolation point.

Importance of 4-Pole Isolation in Industrial Power Distribution

In industrial systems, isolating only the phases is often insufficient. Neutral conductors can carry current under fault or imbalance conditions. A 4-pole switch ensures complete disconnection, eliminating residual voltage risks.

This level of isolation is especially important in systems with sensitive equipment, mixed loads, or complex grounding arrangements. Therefore, a heavy-duty 4-pole motorized load isolation switch significantly improves overall system safety.

Evolution of Motorized Load Isolation Switches

Early isolation switches were manually operated and required physical presence. As industrial automation advanced, motorized operation became necessary to improve efficiency and safety.

Modern motorized load isolation switches integrate seamlessly with control systems. The evolution reflects the shift toward centralized control, remote operation, and enhanced safety standards in industrial environments.

Core Components of Heavy-Duty Motorized Isolation Switch

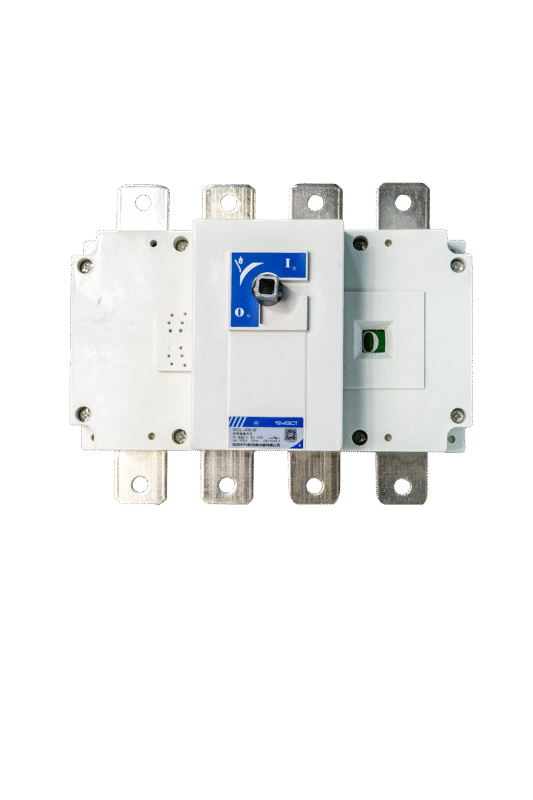

The main components include high-current contacts, a robust switching mechanism, an electric motor drive, and a control interface. The contacts are designed to withstand high electrical and mechanical stress.

The motor drive ensures smooth and reliable operation. Control interfaces allow integration with automation systems, enabling remote switching and status feedback.

What Makes a Switch “Heavy-Duty”

A heavy-duty switch is characterized by high current ratings, strong mechanical endurance, and durable construction. These switches are built to operate reliably under continuous load and frequent switching.

Reinforced housings, high-quality insulation, and arc-resistant designs further distinguish heavy-duty isolation switches from standard models.

How a 4-Pole Motorized Load Isolation Switch Works

Under normal operation, the switch remains closed, allowing power flow. When isolation is required, a control signal activates the motor.

The motor drives the mechanism to open all four poles simultaneously. Mechanical interlocking ensures precise operation. The result is safe, visible, and complete isolation.

Role of the Neutral Pole in 4-Pole Switches

The neutral pole plays a crucial role in fault prevention. In systems with unbalanced loads, the neutral may carry significant current.

By isolating the neutral along with the phases, the switch eliminates potential shock hazards and protects downstream equipment during maintenance.

Manual vs Motorized Load Isolation Switch

Manual isolation switches require physical operation, which can expose operators to risk. Motorized switches allow remote operation, reducing exposure to live equipment.

In large industrial facilities, motorized operation improves response time and operational efficiency. This advantage makes motorized switches the preferred choice in modern installations.

Integration with Industrial Power Distribution Systems

A heavy-duty 4-pole motorized load isolation switch is commonly integrated into switchgear, motor control centers, and main distribution boards.

Its compatibility with industrial power distribution architecture ensures seamless integration. This flexibility supports a wide range of industrial applications.

Applications in Manufacturing Plants

Manufacturing plants rely on safe isolation for maintenance and process control. These switches allow operators to isolate machinery quickly and safely.

By enabling remote disconnection, downtime is minimized. Safety compliance is also enhanced across the facility.

Applications in Utilities and Infrastructure

Utilities and infrastructure systems require reliable isolation under high load conditions. Motorized isolation switches support safe sectionalizing of power networks.

They are widely used in substations, pumping stations, and transportation infrastructure where reliability is critical.

Role in Data Centers and Critical Facilities

Data centers demand high availability and controlled maintenance. A heavy-duty 4-pole motorized load isolation switch allows precise isolation without disrupting other systems.

This controlled approach protects sensitive equipment and supports continuous operation.

Safety Interlocking and Protection Features

Safety interlocks prevent accidental operation under unsafe conditions. Mechanical and electrical interlocks ensure proper sequencing.

Additional protection features may include padlocking, auxiliary contacts, and position indicators. These features enhance operator safety and system integrity.

Remote Control and Automation Capabilities

Motorized isolation switches integrate with SCADA, PLC, and building management systems. Remote operation enables centralized control and monitoring.

This capability supports predictive maintenance and faster response to faults, improving overall system reliability.

Installation Best Practices in Industrial Environments

Proper installation is essential for performance and safety. Correct torqueing, alignment, and wiring practices must be followed.

Adequate clearance and ventilation are also important. Following manufacturer guidelines ensures long-term reliability.

Compliance with Industrial Electrical Standards

These switches are designed to meet international standards such as IEC and UL. Compliance ensures safety, performance, and acceptance by authorities.

Using certified equipment simplifies inspections and reduces regulatory risk.

Maintenance of Heavy-Duty Motorized Isolation Switch

Routine maintenance includes inspection of contacts, motor operation, and control circuits. Lubrication and cleaning may be required periodically.

Preventive maintenance extends service life and ensures reliable operation during critical events.

Common Faults and Troubleshooting

Common issues include motor drive faults and contact wear. Diagnostic indicators help identify problems quickly.

Timely troubleshooting minimizes downtime and prevents secondary damage.

Energy Efficiency and Operational Reliability

Low-resistance contacts reduce power losses and heat generation. Efficient operation contributes to overall energy efficiency.

Operational reliability ensures consistent performance even under demanding conditions.

Environmental and Mechanical Durability

Industrial environments can be harsh. Heavy-duty isolation switches are designed to withstand dust, moisture, vibration, and temperature extremes.

Robust enclosures and corrosion-resistant materials ensure durability.

Selecting the Right Heavy-Duty 4-Pole Isolation Switch

Selection depends on voltage, current rating, switching frequency, and environmental conditions. Motor control voltage and automation compatibility are also important.

Professional assessment ensures the right choice for each application.

Cost and Lifecycle Value Analysis

Although initial costs may be higher, the lifecycle value is significant. Reduced downtime, improved safety, and long service life justify the investment.

A heavy-duty 4-pole motorized load isolation switch delivers strong return on investment over time.

Future Trends in Motorized Isolation Switches

Future designs will focus on smart monitoring, digital diagnostics, and enhanced connectivity. Integration with smart grids and Industry 4.0 systems is increasing.

These advancements will further improve safety and efficiency.

Preguntas frecuentes

What is a heavy-duty 4-pole motorized load isolation switch?

It is a motor-operated switch that isolates three phases and neutral in industrial systems.

Why is a 4-pole switch important?

It ensures complete isolation, including the neutral conductor.

Can it be operated remotely?

Yes, motorized versions support remote control.

Is it suitable for high-current applications?

Yes, it is designed for heavy industrial loads.

How often should maintenance be performed?

Periodic inspection based on usage and environment is recommended.

Does it comply with industrial standards?

Most models comply with IEC and UL standards.

Conclusion

The Heavy-duty 4-pole motorized load isolation switch for industrial power distribution is a cornerstone of modern electrical safety and control. It provides complete isolation, remote operation, and exceptional durability in demanding environments. From manufacturing plants to critical infrastructure, its role is vital.

As industries continue to embrace automation and higher safety standards, this robust isolation solution will remain essential. Investing in the right heavy-duty motorized isolation switch ensures safety, reliability, and long-term operational confidence.